Strict qualification review: Complete production qualifications (including factory certification, supply chain compliance documents, etc.) must be submitted; the completeness and standardization of documents directly affect bidding eligibility.

Requirements for price and production transparency: A breakdown price list (detailed costs by material and process) must be provided, along with machine lists, capacity analysis, and production schedules, requiring in-depth mastery of the entire production process.

Extreme color control: Fabric and printing colors must be strictly checked against Pantone color numbers with no color difference; multiple color swatches must be provided for customer selection to ensure consistency.

Pressure of rapid sampling: Samples must be made within 2-3 days and meet mass production standards; timeliness directly affects the bidding progress.

Requirements for sample standardization: Samples and materials must be classified, packaged, and clearly labeled (including material, color, process, etc.) to reflect professionalism.

Qualification and production transparency response: Integrated 31 years of production qualification documents (including ISO certification, supply chain compliance reports, etc.) and submitted them within 24 hours; created a breakdown price list by "material classification (e.g., 16oz canvas/12oz canvas) + process breakdown (cutting/sewing/silk printing, etc.)", and attached a list of 20 production equipment, daily 500,000-piece capacity analysis, and phased production schedules to clearly present fulfillment capabilities.

Accurate color control: Retrieved standard Pantone color values in advance, collaborated with fabric suppliers to customize 3 types of base fabrics, and produced 10 sets of color swatches for selection; used professional colorimeters for calibration during sampling to ensure color deviation ≤△E1.5 (strict industry standard).

Rapid and standardized sampling: Established a special sampling team to complete 3 sample types (including different materials) within 2 days; classified and packaged by "material-color-process" with QR code labels (parameters viewable by scanning) and attached paper parameter sheets to ensure clear and traceable information.

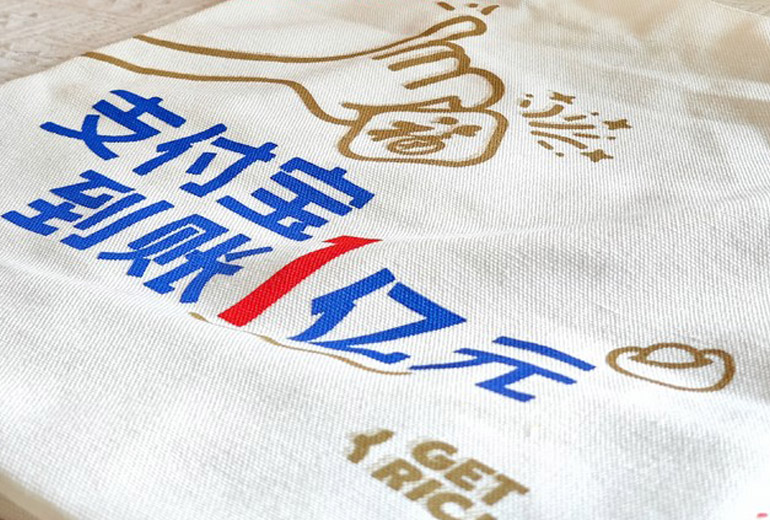

Passed all audits during the bidding stage; 10 million canvas bags were mass-produced and delivered as planned; color consistency and material stability passed random inspection with 100% qualification, becoming the core supplier of Alipay's offline brand materials. This cooperation confirms Gahumi's supply chain collaboration and detail control capabilities in large-scale customization.

🚩About the Client

Alipay, a world-leading payment technology platform, empowers commercial and life scenarios through technology. Customized brand materials must match its brand tone of "efficiency, standardization, and high quality", with strict screening standards for suppliers' comprehensive strength (qualifications, capacity, quality control).

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric printing enterprise integrating R&D, design, production, and sales with 31 years of production experience. Relying on a 5,000-square-meter standardized factory, 20 sets of automatic production equipment, and a team of over 300 professionals, it has established a full-chain control system from fabric procurement to finished product delivery. It excels in cost control and quality stability in large-scale customization, and has become a trusted partner of brands in technology, retail, and other fields with "supply chain collaboration + extreme service".

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

From qualification submission to sample delivery, it only took 3 days. Gahumi's breakdown price list and capacity plan made costs and delivery Rhythm clear at a glance; Pantone color check had zero deviation, and even 10 million units could ensure stable quality. Their comprehensive strength is trustworthy."

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap